H07RN-F Cable can provide high flexibility and have the capacity to withstand weather, oil/grease, mechanical and thermal stresses.

H07RN-F Cable can provide high flexibility and have the capacity to withstand weather, oil/grease, mechanical and thermal stresses.

They are used for handling equipment, mobile power supplies, worksites, stage and audio visual equipment, port areas and dams. Also for use in drainage and water treatment, cold environments and severe industrial environments.

Standard VDE 0282 Part-4, IEC 60245-4

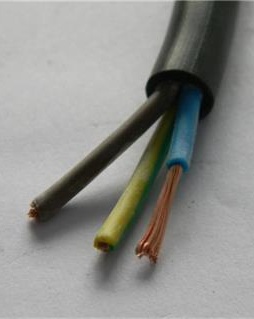

Cable construction Conductor: Flexible bare copper wire / tinned copper wire , class 5

Insulation: Rubber compound

Outer sheath: Neoprene Rubber

Core identification code: Up to 5 cores: colour-coded according to VDE 0293-308,

From 6 cores: black with white numbers

Protective conductor: G = with GN-YE protective conductor

X = without protective conductor Jacket color: Black or others as per requirements

Technical characteristics:Rated voltage: 450/750V

Test voltage: 2500volts

Temperature Rating(Flexing use): -25°C to +60°C

Temperature Rating(Fixed installation): -40°C to +60°C.

Short circuit temperature: 200°C

Minimum Bending Radius: 6D(Flexing used) ,4D(Fixed installation)

Insulation resistance: 20 MΩ x km

| No. of Core | Conductor Size | Conductor | Insulation | Outer sheath Nominal Thickness | Approx. Cable Dia. | ||

| Single wire dia. | Nominal Thickness | Single layer | Double layer | ||||

| Inner sheath | Outer sheath | ||||||

| No.s | mm2 | mm | mm | mm | mm | mm | mm |

| 2 | 1 | ≤0.21 | 0.8 | 1.3 | — | — | 8.7 |

| 2 | 1.5 | ≤0.26 | 0.8 | 1.5 | — | — | 9.5 |

| 2 | 2.5 | ≤0.26 | 0.9 | 1.7 | — | — | 11.8 |

| 2 | 4 | ≤0.31 | 1 | 1.8 | — | — | 13.5 |

| 2 | 6 | ≤0.31 | 1 | 2 | — | — | 15.2 |

| 2 | 10 | ≤0.41 | 1.2 | 3.1 | 1.2 | 1.9 | 20.9 |

| 2 | 16 | ≤0.41 | 1.2 | 3.3 | 1.3 | 2 | 23.8 |

| 2 | 25 | ≤0.41 | 1.4 | 3.6 | 1.4 | 2.2 | 27.7 |

| 3 | 1 | ≤0.21 | 0.8 | 1.4 | — | — | 9.4 |

| 3 | 1.5 | ≤0.26 | 0.8 | 1.6 | — | — | 10.2 |

| 3 | 2.5 | ≤0.26 | 0.9 | 1.8 | — | — | 12.7 |

| 3 | 4 | ≤0.31 | 1 | 1.9 | — | — | 14.5 |

| 3 | 6 | ≤0.31 | 1 | 2.1 | — | — | 16.2 |

| 3 | 10 | ≤0.41 | 1.2 | 3.3 | 1.3 | 2 | 22.5 |

| 3 | 16 | ≤0.41 | 1.2 | 3.5 | 1.4 | 2.1 | 25.5 |

| 3 | 25 | ≤0.41 | 1.4 | 3.8 | 1.5 | 2.3 | 29.7 |

| 3 | 35 | ≤0.41 | 1.4 | 4.1 | 1.6 | 2.5 | 33.2 |

| 3 | 50 | ≤0.41 | 1.6 | 4.5 | 1.8 | 2.7 | 38.1 |

| 3 | 70 | ≤0.51 | 1.6 | 4.8 | 1.9 | 2.9 | 43.8 |

| 3 | 95 | ≤0.51 | 1.8 | 5.3 | 2.1 | 3.2 | 49.4 |

| 3 | 120 | ≤0.51 | 1.8 | 5.6 | 2.2 | 3.4 | 53.6 |

| 3 | 150 | ≤0.51 | 2 | 6 | 2.4 | 3.6 | 63.4 |

| 3 | 185 | ≤0.51 | 2.2 | 6.4 | 2.5 | 3.9 | 65.7 |

| 3 | 240 | ≤0.51 | 2.4 | 7.1 | 2.8 | 4.3 | 74.4 |

| 3 | 300 | ≤0.51 | 2.6 | 7.7 | 3.1 | 4.6 | 76.5 |

| 4 | 1 | ≤0.21 | 0.8 | 1.5 | — | — | 10.4 |

| 4 | 1.5 | ≤0.26 | 0.8 | 1.7 | — | — | 11.3 |

| 4 | 2.5 | ≤0.26 | 0.9 | 1.9 | — | — | 14 |

| 4 | 4 | ≤0.31 | 1 | 2 | — | — | 16 |

| 4 | 6 | ≤0.31 | 1 | 2.3 | — | — | 18.1 |

| 4 | 10 | ≤0.41 | 1.2 | 3.4 | 1.4 | 2 | 24.6 |

| 4 | 16 | ≤0.41 | 1.2 | 3.6 | 1.4 | 2.2 | 28 |

| 4 | 25 | ≤0.41 | 1.4 | 4.1 | 1.6 | 2.5 | 33 |

| 4 | 35 | ≤0.41 | 1.4 | 4.4 | 1.7 | 2.7 | 36.9 |

| 4 | 50 | ≤0.41 | 1.6 | 4.8 | 1.9 | 2.9 | 42.2 |

| 4 | 70 | ≤0.51 | 1.6 | 5.2 | 2 | 3.2 | 48.7 |

| 4 | 95 | ≤0.51 | 1.8 | 5.9 | 2.3 | 3.6 | 55.3 |

| 4 | 120 | ≤0.51 | 1.8 | 6 | 2.4 | 3.6 | 59.6 |

| 4 | 150 | ≤0.51 | 2 | 6.5 | 2.6 | 3.9 | 70.6 |

| 4 | 185 | ≤0.51 | 2.2 | 7 | 2.8 | 4.2 | 73.3 |

| 4 | 240 | ≤0.51 | 2.4 | 7.7 | 3.1 | 4.6 | 82.9 |

| 4 | 300 | ≤0.51 | 2.6 | 8.4 | 3.3 | 5.1 | 85.2 |

| 5 | 1 | ≤0.21 | 0.8 | 1.6 | — | — | 11.5 |

| 5 | 1.5 | ≤0.26 | 0.8 | 1.8 | — | — | 12.4 |

| 5 | 2.5 | ≤0.26 | 0.9 | 2 | — | — | 15.4 |

| 5 | 4 | ≤0.31 | 1 | 2.2 | — | — | 17.8 |

| 5 | 6 | ≤0.31 | 1 | 2.5 | 1 | 1.5 | 20.1 |

| 5 | 10 | ≤0.41 | 1.2 | 3.6 | 1.4 | 2.2 | 27.1 |

| 5 | 16 | ≤0.41 | 1.2 | 3.9 | 1.5 | 2.4 | 31 |

| 5 | 25 | ≤0.41 | 1.4 | 4.4 | 1.7 | 2.7 | 36.5 |

| 6 | 1.5 | ≤0.26 | 0.8 | 2.5 | 1 | 1.5 | 14.8 |

| 6 | 2.5 | ≤0.26 | 0.9 | 2.7 | 1.1 | 1.6 | 18.1 |

| 6 | 4 | ≤0.31 | 1 | 2.9 | 1.2 | 1.7 | 20.7 |

| 12 | 1.5 | ≤0.26 | 0.8 | 2.9 | 1.2 | 1.7 | 19.3 |

| 12 | 2.5 | ≤0.26 | 0.9 | 3.1 | 1.2 | 1.9 | 23.7 |

| 12 | 4 | ≤0.31 | 1 | 3.5 | 1.4 | 2.1 | 27.6 |

| 18 | 1.5 | ≤0.26 | 0.8 | 3.2 | 1.3 | 1.9 | 22.7 |

| 18 | 2.5 | ≤0.26 | 0.9 | 3.5 | 1.4 | 2.1 | 28.1 |

| 18 | 4 | ≤0.31 | 1 | 3.9 | 1.6 | 2.3 | 32.6 |

| 24 | 1.5 | ≤0.26 | 0.8 | 3.5 | 1.4 | 2.1 | 26.6 |

| 24 | 2.5 | ≤0.26 | 0.9 | 3.9 | 1.6 | 2.3 | 33.1 |

| 36 | 1.5 | ≤0.26 | 0.8 | 3.8 | 1.5 | 2.3 | 30.4 |

| 36 | 2.5 | ≤0.26 | 0.9 | 4.3 | 1.7 | 2.6 | 38.1 |

Our cables, wires, conductors are usually packed in wood drum, Iron-wooden drum. Steel reel will also be used if required by client. For some short length, such as 50m, 150m, 300m, the conductor can also be packed in coil.

Product standard, Conductor Size, Quantity, Sea port/Airport for delivery, etc.

Usually we will quote to you within 24 hours after get your detailed inquiry information

We have exported to 100+ countries/area. We have rich export experience and will try our best to serve you and meet your needs. You can contact us for detailed communications.

Normally we offer EXW,FCA,FOB,CNF,CIF according to customer requirements.

According to different order quantity, the lead time is different. Normally it is 7- 30 days for production. For large quantities, the goods will be shipped in partial times according to schedule.